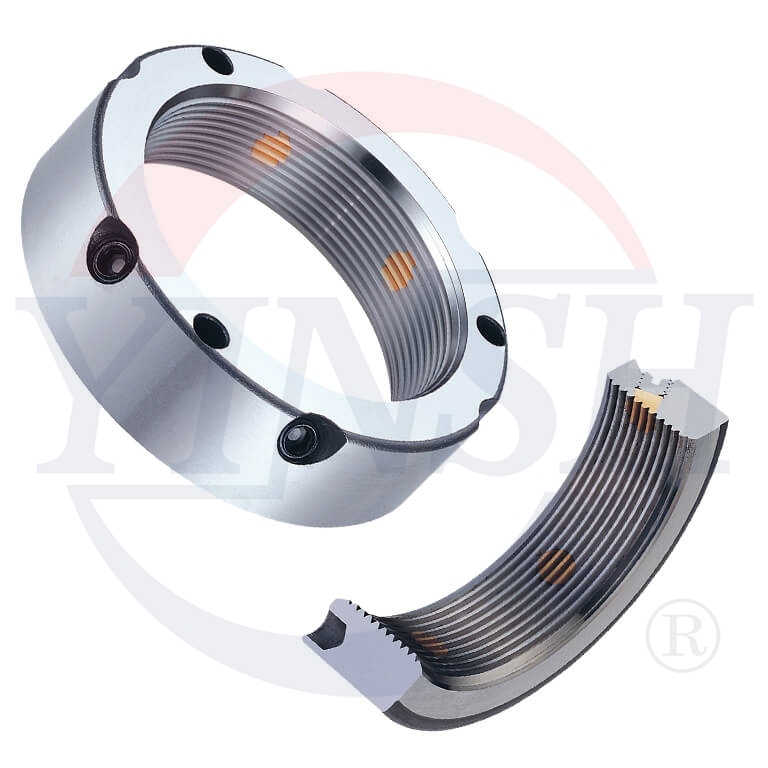

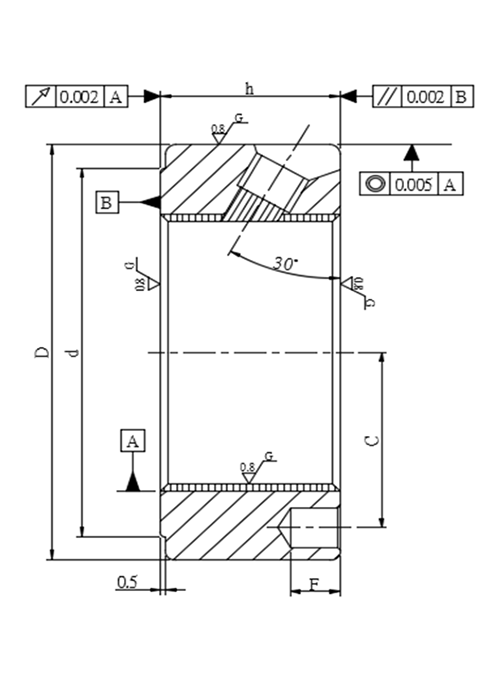

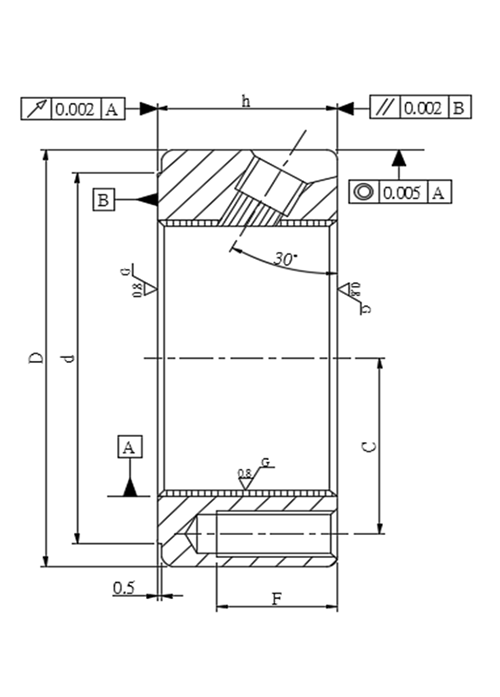

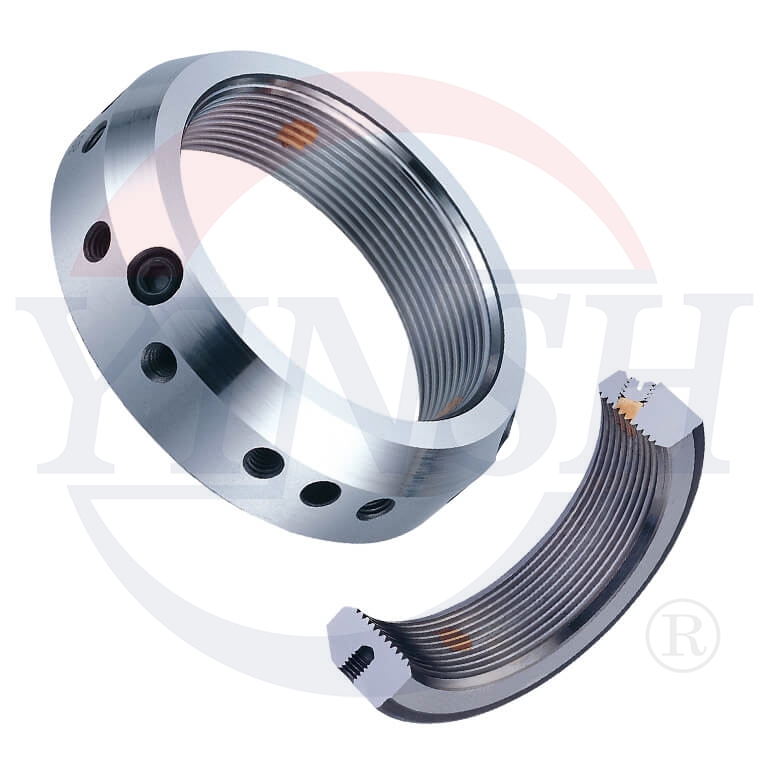

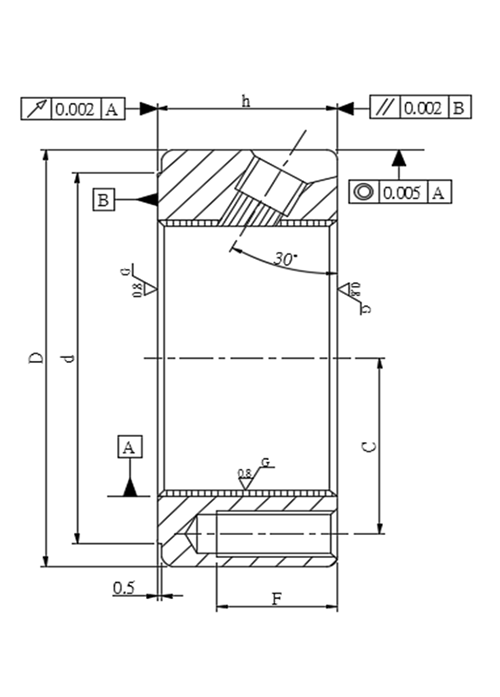

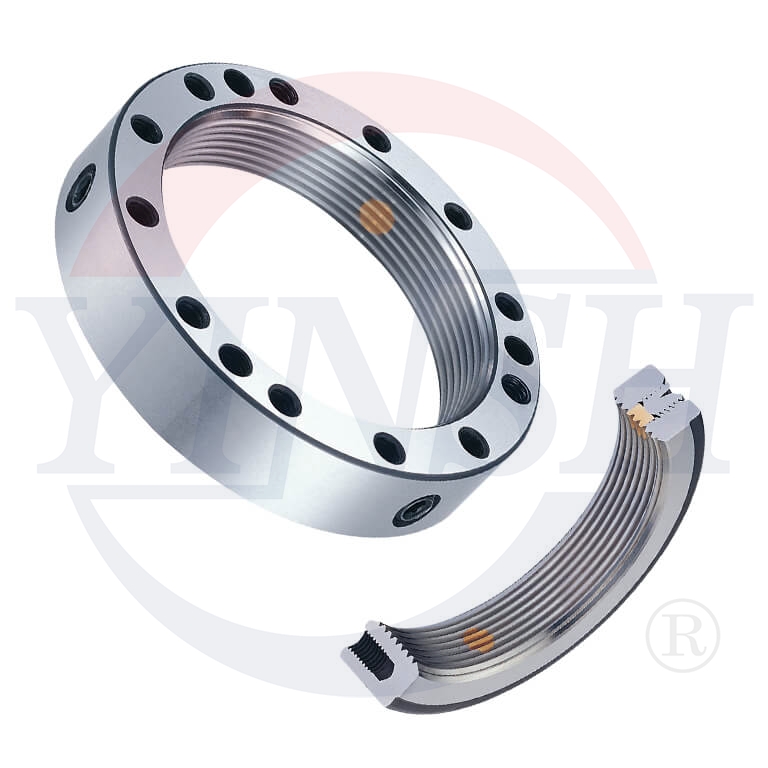

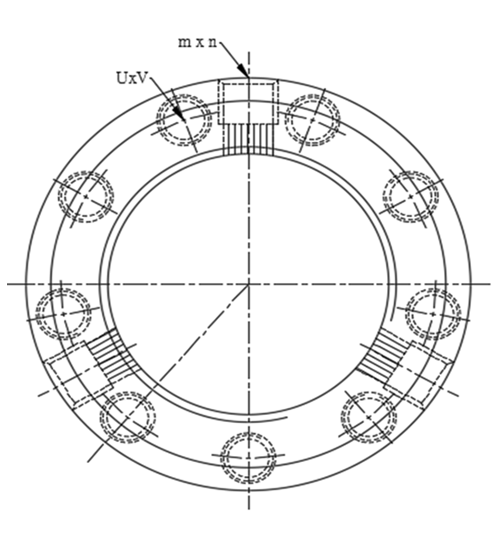

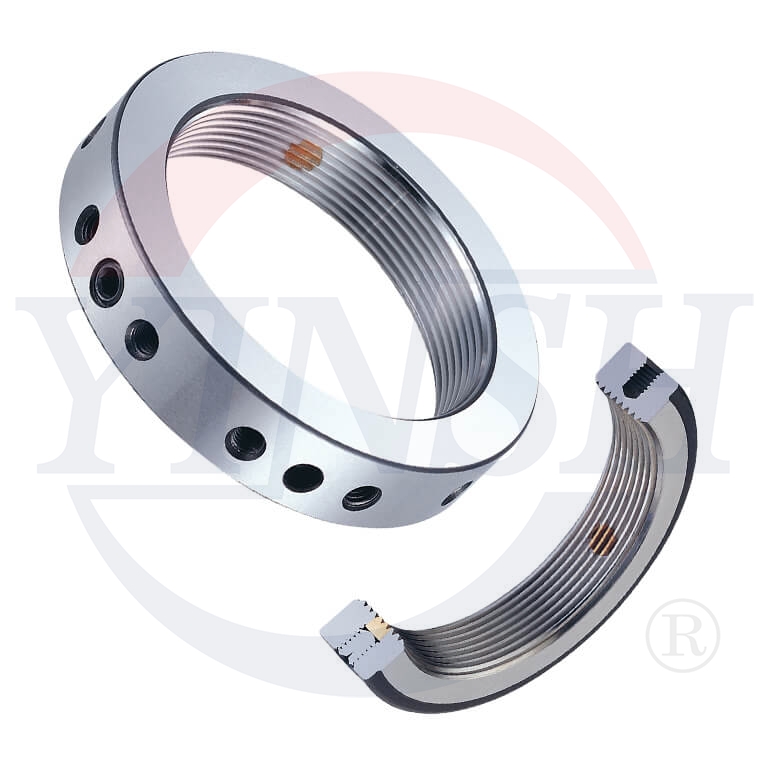

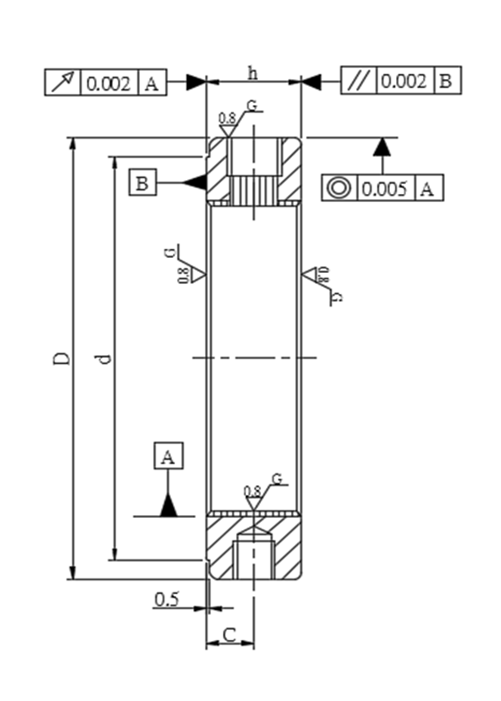

SBL-A Precision Locknut

Lock screws intersect at a 30° angle. Superior to traditional locknuts with only 3 lock screws, the SBL-A employ 6 lock screws to the axis. Perfect mesh. Precision and balanced compression. Zero loosening under any load or speed. Inner threads, outer skirts, clamping and trailing rims are all precision ground, minimizing noise and vibration.

Material Composition:SCM440(42CrMo4)

Thread Precision:ISO 4H

Parallelism:0.002mm

Hardness:HRC 48° ~ 52°

Edge Bevel:0.002mm

Concentricity:0.005mm

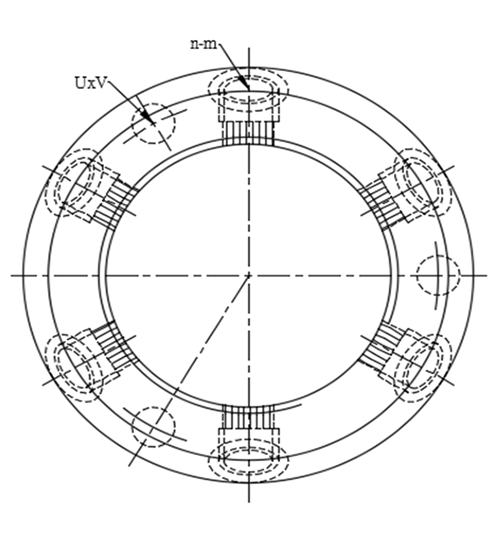

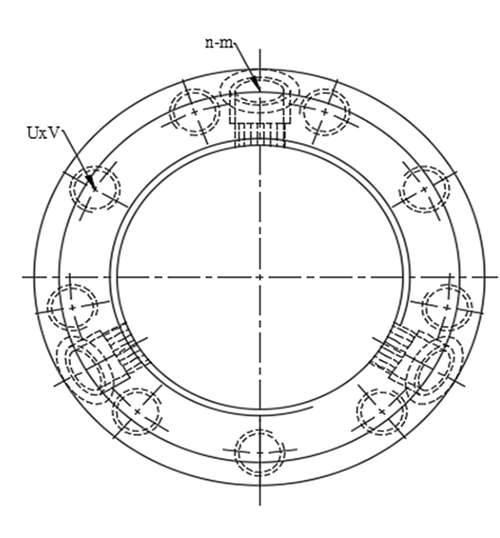

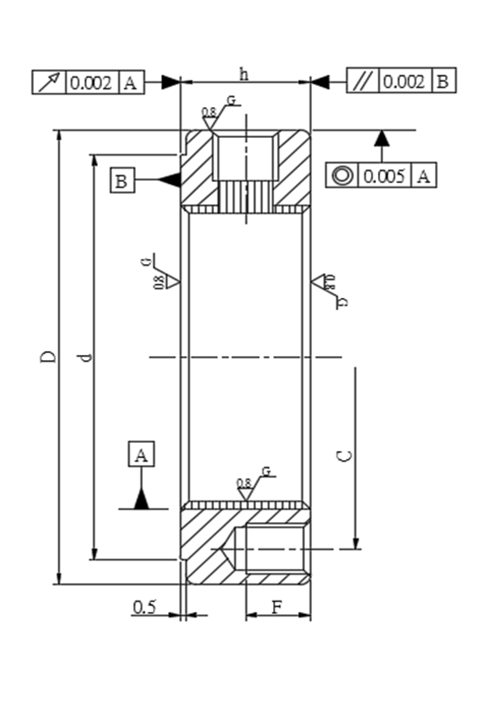

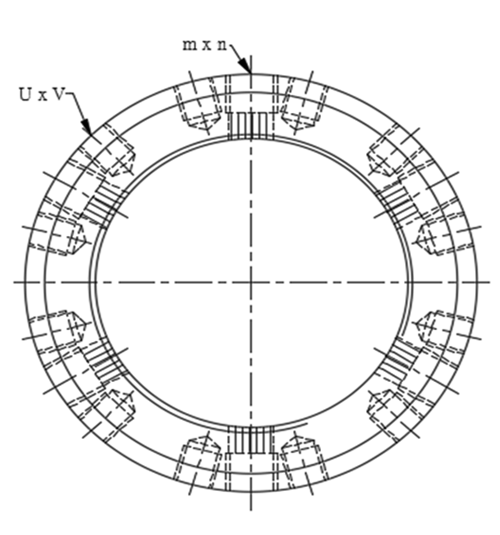

SBL-B Precision Lock Nut

This design differs from the SBL-A in that there are balance adjustment screws added at the trailing surface, making for added convenience in precision adjustment. Balance adjustment screw holes can be fitted with screw-in plugs (option), eliminating high frequency noise and subsequent vibration.

Material Composition:SCM440(42CrMo4)

Hardness:HRC48° ~52°

Thread Precision:ISO 4H

Parallelism: 0.002mm

Edge Bevel:0.002mm

Concentricity:0.005mm

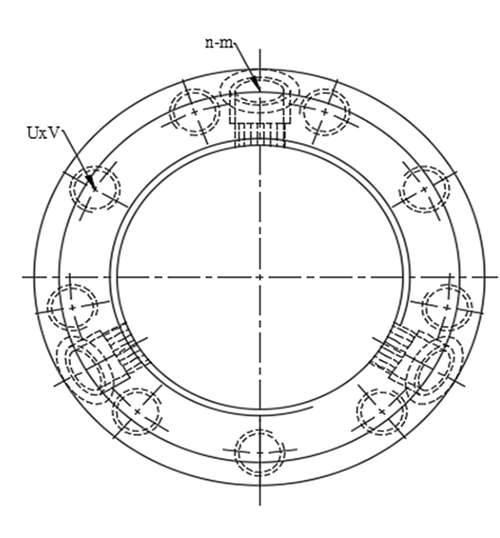

SBL-C Precision Lock Nut

The difference with this design is that the balance adjustment screws tighten from the outer skirt at a radial angle. It is the optimal choice for spindles with restricted space. Balance adjustment screw holes can be fitted with screw-in plugs (option), eliminating high frequency noise and subsequent vibration.

Material Composition:SCM440(42CrMo4)

Hardness:HRC48° ~52°

Thread Precision:ISO 4H

Parallelism: 0.002mm

Edge Bevel:0.002mm

Concentricity:0.005mm

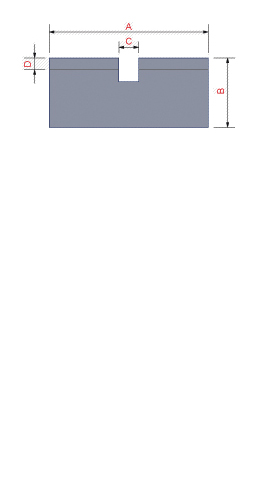

SBL-D Precision Locknut

For spindles with exceptionally restricted or narrow space, this model is ideal in that it is super thin and requires no additional tooling or components to do its job. For thread sizes under M45 we offer the SBL-D with 3 lock screws, and for larger threads we offer the SBL-D with 6 lock screws. Balance adjustment screw holes can be fitted with screw-in plugs(option), eliminating high frequency noise and subsequent vibration.

Material Composition:SCM440(42CrMo4)

Thread Precision:ISO 4H

Parallelism:0.002mm

Hardness:HRC 48° ~ 52°

Edge Bevel:0.002mm

Concentricity:0.005mm

SBL-E Precision Locknut

This model is for spindles with exceptionally restricted or narrow space, particularly where any adjustment from the trailing surface is inconvenient. Balance adjustment screw holes can be fitted with screw-in plugs(option), eliminating high frequency noise and subsequent vibration.

Material Composition:SCM440(42CrMo4)

Hardness:HRC48° ~52°

Thread Precision:ISO 4H

Parallelism: 0.002mm

Edge Bevel:0.002mm

Concentricity:0.005mm

At high speeds, the threaded holes for lock or balance screws generate high frequency noise and subsequent vibration. Our answer to the noise elimination is our screw-in plugs (option). Made of Polycarbonate Fiber, these plugs are extremely light and stable. An added benefit is the prevention of any rust build up.

More